SEE Electrical 3D Panel

Design

Annual subscription

- Efficient 3D cabinet layout designing.

- Extensive 3d symbol libraries.

- Wire channels and rails management.

- Collisions checking.

- Documentation Designer.

- Copper busbar design.

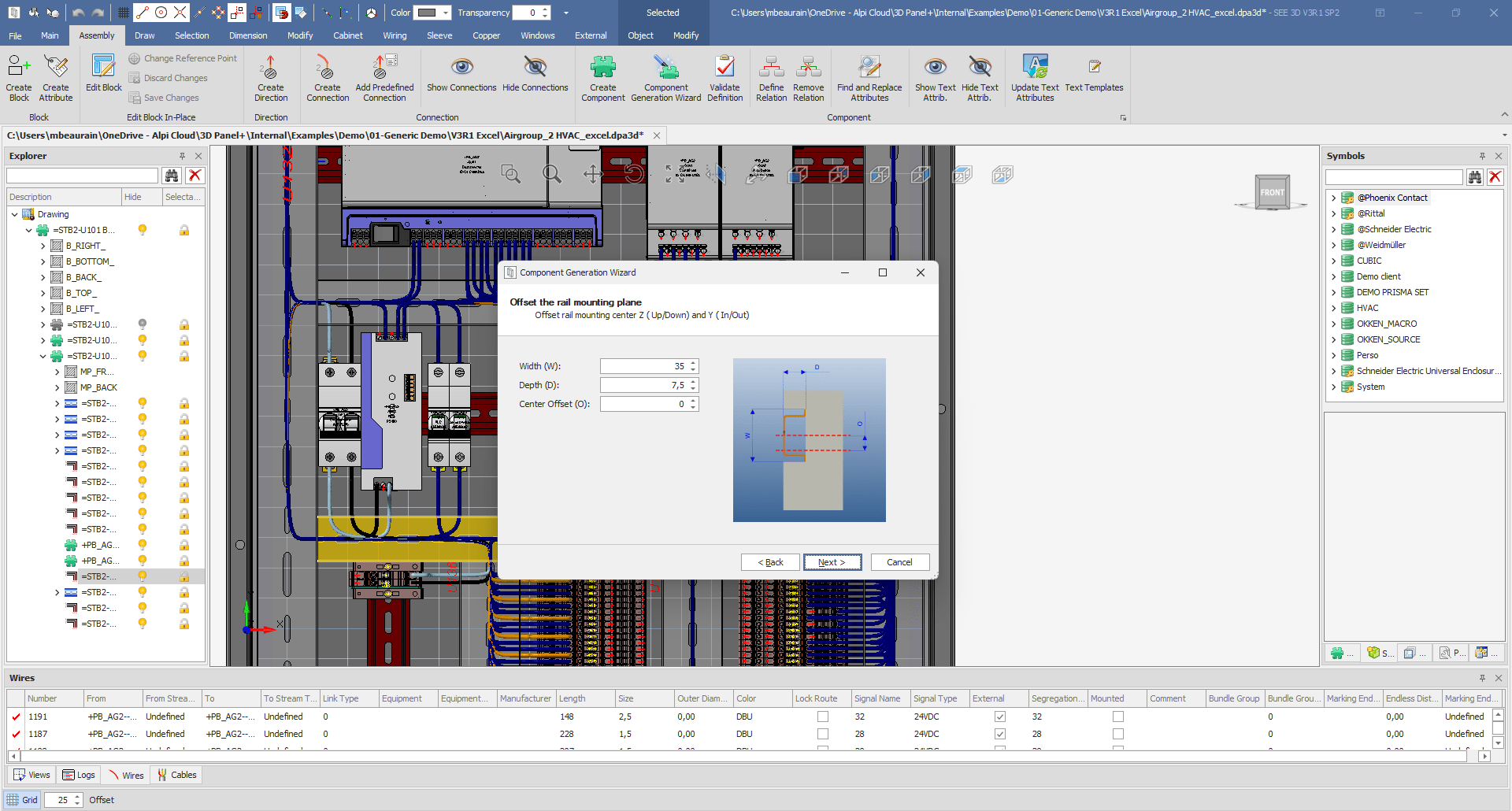

- Smart 3D parts creation.

Manufacturing

Annual subscription

- Automatic wire routing and lengths calculation.

- Creation of drilling plan.

- Generation of list of wires From >> To.

- End fitting management.

- Other outputs for manufacturing.

- Control Cabinet Manufacturing 4.0.

Design features plus:

Overview

SEE Electrical 3D Panel is a program dedicated to the designing and manufacturing electrical cabinets, switchboards and panels.

SEE Electrical 3D Panel allows you to design and manufacture electrical cabinets by using a professional and intuitive interface. Application reads data from electrical projects made in SEE Electrical and SEE Electrical Expert software or from other electrical cad systems.

SEE Electrical 3D Panel is a standalone application, and can be used like an add-on too in SEE Electrical or SEE Electrical Expert respectively. This software can be purchased in two levels – Design and Manufacturing.

Each level offers a range of services at a different price point so that you can select the level that suits your company needs, but it is recommended to buy full version, to enjoy all the integrated possibilities.

Production offices that use electrical documentation prepared in our SEE programs, should use this application to build cabinets.

Benefits

Streamlined Design Integration

Improved Quality by streamlining the flow of electrical diagrams with cabinet layouts design with using the same electrical database.

Time-Saving Design and Manufacturing

Improved Efficiency by saving time on the stage of designing and manufacturing the electrical cabinet.

Automated Functions for Increased Productivity

Improved Productivity thanks to the automatic functions, like wire routing and list generation of manufacturing lists.

Features

Introduction

Advanced Cabinet Layout Design

Seamless Integration with Electrical Diagrams

Automatic Electrical Wire Routing

Comprehensive Manufacturing Outputs

Documents & videos

Explore our 3D electrical cabinet design software!

Versions

Versions

Discover all key features of the latest SEE Electrical 3D Panel release.

Training

Get an in-depth insight to our electrical engineering software by requesting a training course that suits you.

We have been providing training for electricians since the previous century. We know that a good atmosphere and the right equipment greatly accelerate learning progress. That’s why, in addition to professional trainers, the right equipment and software, our courses for electricians feature many amenities that make learning a pleasure.

→ Fill the Training Request now

Design

Annual subscription

- Efficient 3D cabinet layout designing.

- Extensive 3d symbol libraries.

- Wire channels and rails management.

- Collisions checking.

- Documentation Designer.

- Copper busbar design.

- Smart 3D parts creation.

Manufacturing

Annual subscription

- Automatic wire routing and lengths calculation.

- Creation of drilling plan.

- Generation of list of wires From >> To.

- End fitting management.

- Other outputs for manufacturing.

- Control Cabinet Manufacturing 4.0.

Design features plus:

Related Products

-

SEE Electrical

Create electrical diagrams with SEE Electrical in just a few clicks!

→ Learn More -

SEE Electrical Expert

All the power of Electrical CAD dedicated to industrial automation and electrical harnesses

→ Learn More