SEE Electrical 3D Shop Floor

Contact us

Annual subscription

Are you interested in this add-on?

Please click on the

‘Buy now’

button and fill out the form.

We will respond to you as soon as possible.

Overview

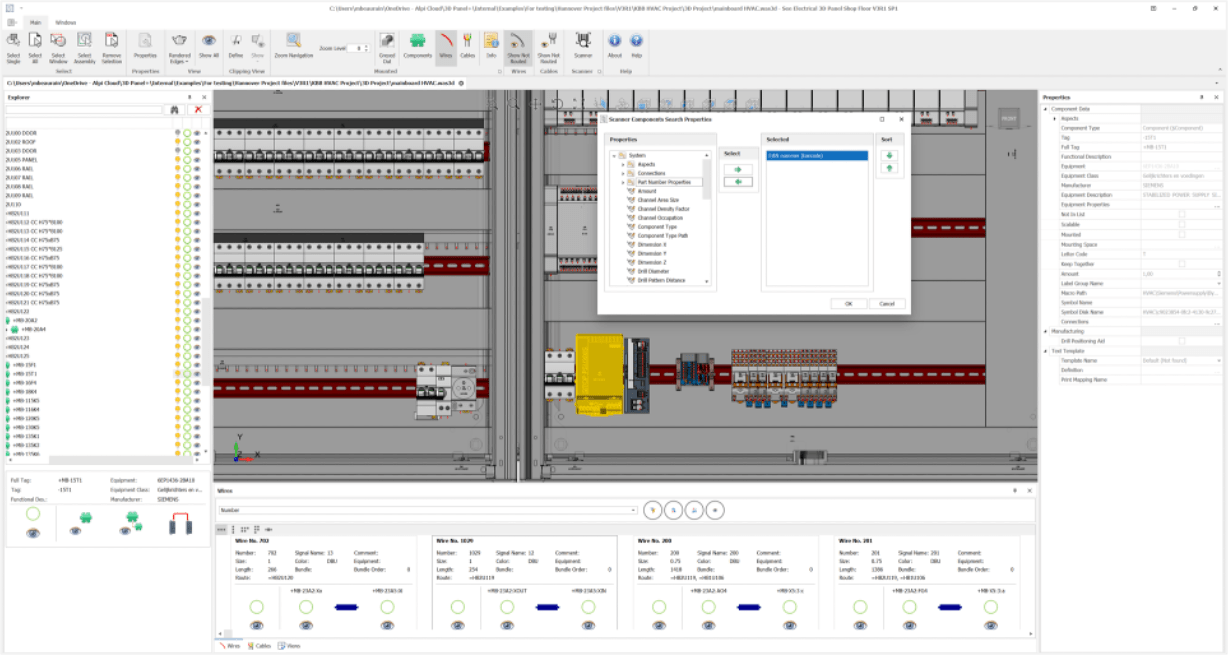

SEE Electrical 3D Shop Floor is a standalone application dedicated to producing stage of electrical cabinet.

SEE Electrical 3D Shop Floor is the perfect tool to save time in panel manufacturing. It is a software standalone application intended to assist electrical cabinets manufacturing, by enabling you to visualize and manipulate appropriately SEE Electrical 3D Panel projects.

The tool provides extended possibilities for tracking devices installation and panel wiring.

Benefits

Improved Productivity

Increase productivity through the visualization of the virtual cabinet model on the touch screen, enabling electricians to assemble more electrical cabinets efficiently during their work.

Improved Efficiency

Save time at every stage of mounting electrical cabinets with easy control and tracking of the process.

Improved Quality

Enhance quality by producing electrical cabinets without costly errors, particularly in cabinet wiring.

Features

Assisting in the assembly of electrical cabinets

You can open the cabinet diagram in the 3D application, and visualize what you want. You have clear view on devices which need to be mounted with their exact position. Easy location of the elements inserted in the 3D model like rails, components, walls helps you to be accurate. You can look for the component, you can zoom, rotate, filter, select assembled elements. Advanced searching and filtering options are available to quickly locate your equipment, with code, producers and parameters too. User can see real view of 3d symbols with connection points and name used by designer. Advanced visualization of wire and cable connections

This most important for the electrician activity like connecting electrical terminals is supported by special filtering and visualization possibilities. The connection points are visualized in the component: for example, in the circuit breaker. In the special wire and cable windows you will see what was connected, what should be. The popular list From >> Too is displayed. By clicking on selected wire in the wire window, you will see such wire on the screen. Routed and not routed wires can be displayed. Touch-screen compatibility and barcode scanners support

The application is compatible with Touch-screen function. Selected devices are highlighted and user can validate the mounting with a finger touch. User can select wire in the list by using mouse, finger or by barcode engraved on the wire. Distance measurement

This important function informs you about distances declared by design office. You can easy check the real distance and work with designer on needed correction, to be compliant with standards.

Validation of assembling by scanning functionality

Scanners functionality enable you to identify the components, wires, and cables and locate where to install them by scanning their barcode or QR code. When a scanner event is triggered, the process of comparing the data from the barcode or QR code is used, according to the selected property in the wires, cables and components. Thanks to this, you can be sure if all elements are mounted and connected. Validation of assembling and history

Each step can be saved according to the assembly process and exported to the Excel file, to ease future repetitive work.

Electrical 3D projects

This application works with projects made by designer using SEE Electrical 3D Panel Design software. It is recommended, that the project which will be realized, firstly should be checked. The application detects any inconsistencies in the catalog codes and 3D symbols used by the designer. Standalone application

As a stand-alone program, it can be used directly in the production hall during the production of a cabinet. The program is secured by an online license.

Versions

SEE Electrical Expert Versions

Discover all key features of the latest release of SEE Electrical Expert.

Training

Get an in-depth insight to our electrical engineering software by requesting a training course that suits you.

Using the SEE Electrical 3D Shop Floor software is not difficult, but it can be more precise and faster. During the SEE Electrical 3D Panel training we pass on knowledge about efficient using.

→ Fill the Training Request now

Contact us

Annual subscription

Are you interested in this add-on?

Please click on the

‘Buy now’

button and fill out the form.

We will respond to you as soon as possible.

Related Products

-

SEE Electrical Expert

SEE Electrical Expert All the power of Electrical CAD dedicated to industrial automation and electrical harnesses

→ Learn More -

SEE Electrical

Create electrical diagrams with SEE Electrical in just a few clicks!

→ Learn More -

SEE Electrical 3D Panel

Optimize your electrical cabinet’s design and manufacturing

→ Learn More